|

Human errors within production environments are likely to cover the majority of all issues raised within a production workflow. High labor costs and the ability to act flexible while

producing on-demand require a high level of intelligent automation with the smallest possible rate of manual touchpoints. On our path to strive towards single-click automation we

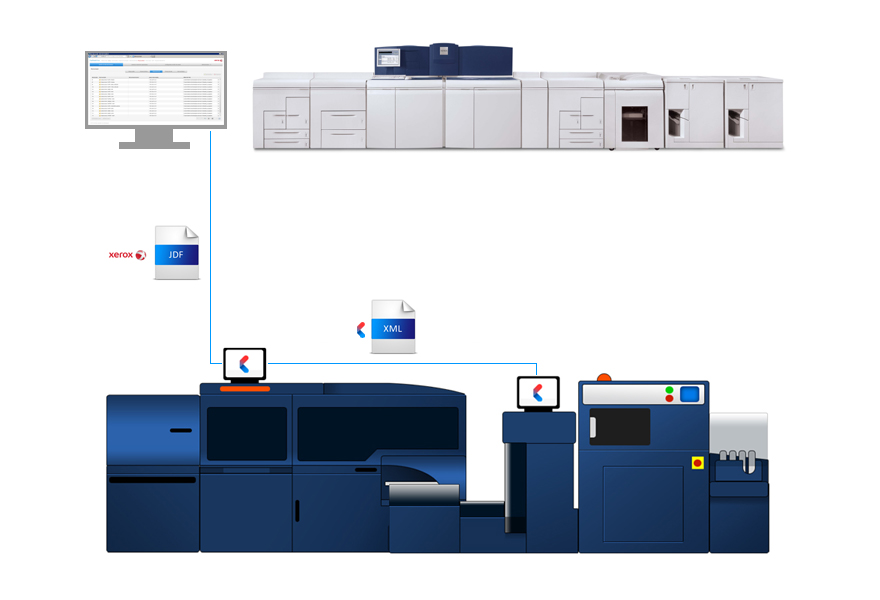

partnered back in 2014 with Xerox in order to combine forces and launch the next level in JDF powered books-of-one automation.

Xerox FreeFlow Core

Xerox FreeFlow Core is the next generation workflow solutions from Xerox. With its browser-based, drag-and-drop operation FreeFlow Core is an end-to-end solution that can help you

automate any step in your print workflow. From version 4.0, FreeFlow Core is ready to output postpress Integrated Plus JDF tickets towards in-line placed C.P. Bourg BB3202 perfectbinders

and Challenge CMT130 and CMT330 trimmers equipped with BBU cover-to-content matching and TXE auto-setup.

What are my benefits?

The direct-JDF approach will eliminate all manual touchpoints to the absolute minimum and setup is handled automatically while being sure of 100% integrity. The solution was designed

from the ground up to be straightforward, easy to implement, secure and lightning fast. The direct-JDF approach without the need for additional conversion software, 3rd party plugins or license keys

ensures troublefree operation and high return on investment.

How does it work?

With the Integrated Plus exportation option enabled in FreeFlow Core each time a new job is submitted to the printer queue FreeFlow Core will generate a postpress JDF ticket and drops this predefined

XML file over the network onto the BBU Barcode System PC.

The BBU software senses in realtime for incoming JDF tickets, identifies the file and strips all the desired data to the BBU repository. As the bookblock arrives in the compiler-area of the perfectbinder

the set is completed, transfered and a production barcode is read. When the bookblock is delivered inside the carriage-clamp of the Bourg binder, the stored barcode is compared towards the barcode as being printed

on the bookcover.

In case of a positive match between bookblock and cover the binder will initiate a binding cycle and the BBU systems pulls the actual bookblock thickness from the binder

(as being measured inside the carriage-clamp). The thickness is stored for the corresponding job inside the repository and all needed setup data for the 3-side trimmer will be calculated and handed over to the

TXE Barcode System. As the book arrives on the topshelf position of the coolingtower of the Challenge trimmer a production barcode is read and the corresponding job-data is loaded from the repository of the TXE

Barcode System initiating a fast, fully automatic size-change of the trimmer.

|

|